In polyurethane processing, manufacturers always use polyester polyols as important raw materials, to make prepolymers with isocyanates or as chain extenders or curatives. Due to the good oxidation and UV resistance, good wear and tear resistance, good heat performance and solvent resistance. Many polyurethane parts feature polyester polyols to prepare them for the toughest environments and applications.But there is one weak point of these great materials: hydrolysis intolerance. A part made of polyester polyol can gradually lose its properties in a humid warehouse due to hydrolysis. The same part though, if is used in water, may survive longer, because the generated acid from hydrolysis can be washed away.

High Hydrolysis Resistance of MPO Polyester Polyols

Now, Gantrade has some good news to share: The polyester polyols based on 2-methyl-1,3-propanediol, also known as MPO, offer very good hydrolysis resistance with all the other good properties. The chart below shows the comparison of MPO polyester polyol hydrolysis to other commonly available polyester polyols.

While 1,4-Butanediol, ethylene glycol, and even hexanediol-based adipate polyester polyols hydrolyze quickly under the experiment condition---Mixed with 10 percent weight water, heated to 90C for extended hours. The degree of hydrolysis is monitored by titrating the acid number --CA6010 is the adipate/MPO polyester polyol which showed very good stability, doesn’t hydrolyze. ( see CA6010 in light purple color on the bottom of the chart).

Although this chart is a hydrolysis demonstration of the polyester polyols, not the polyurethane parts, the graph illustrates the same tendency of materials containing these components.

Beyond the regular polyester polyols, we compared caprolactone and PTMEG co-polyol vs MPO polyester polyol. The high molecular weight caprolactone polymer PCL, regarded as the nice combination of a polyether and polyester, gathers the benefits of both ether and ester polyol properties. On the hydrolysis front, however, PCL is less superior to MPO polyester polyols.

Considered as the utmost base component for a high-performance coatings In the polyester-based coating industry, NPG offers great non-yellowing and gloss retention in outdoor applications; water resistance in boat or watercraft coatings, and serves as the high performance standard in can/coil coatings and powder coatings. When we take a look at the next comparison chart, it is clear that MPO has the ability to share the crown in these areas.

Hydrolysis:

MPO’s High Gloss Retention:

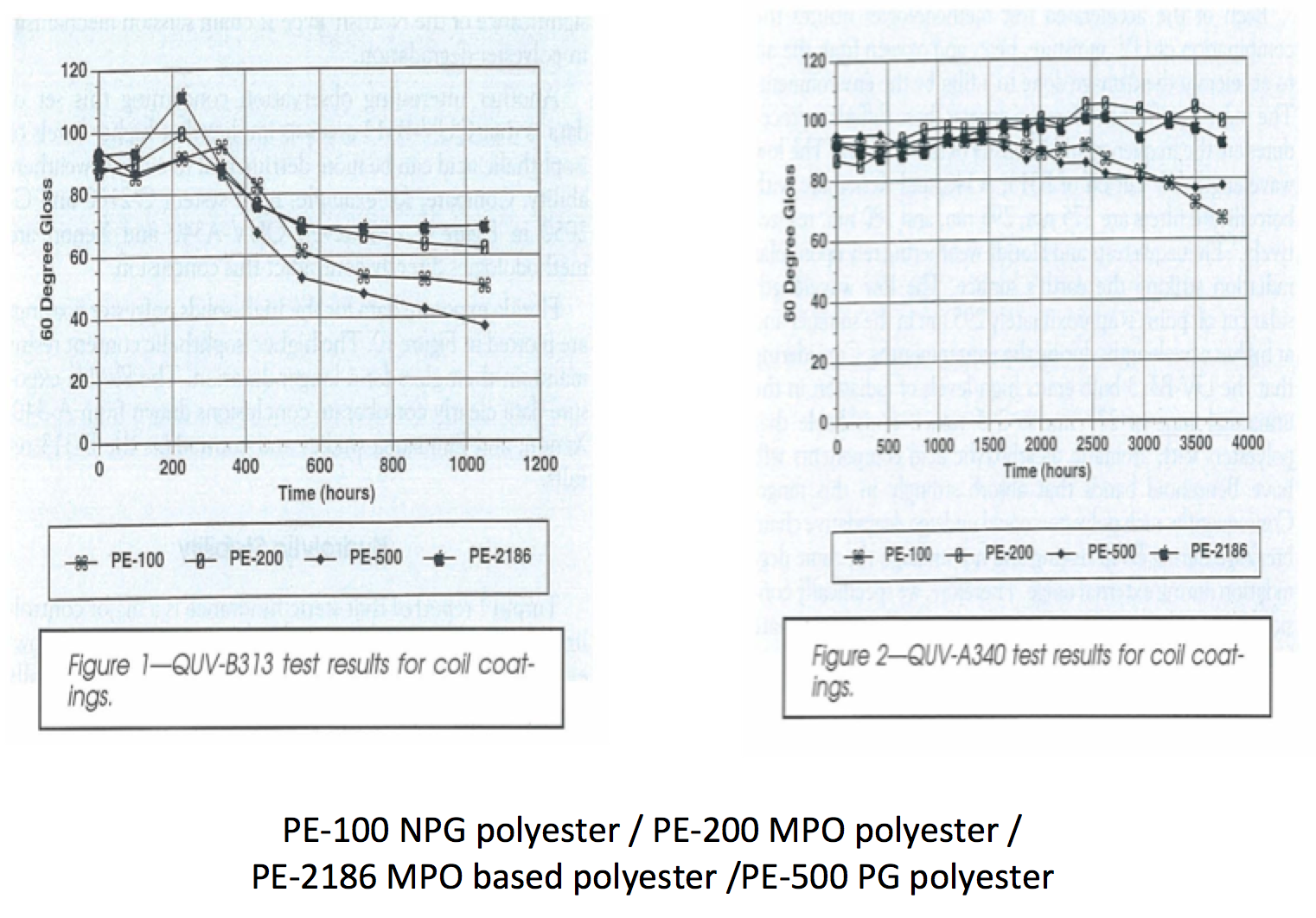

As referenced in the article, “C.Sullivan & C. Cooper, ARCO Chemical Company, ” the orbital occupation of the methylene group is not the defining factor of oxidation/destruction by UV light. The following test proves that MPO has better UV resistance than NPG in some cases. In the chart below, figures show that the MPO-based formulation PE 2186 and PE-200 both have better gloss retention than NPG PE-100 and PG PE-500.

Process Advantage of MPO in Manufacturing

It as clearly illustrated in the above graph that propylene glycol(PG) based polyester formulations gave the least UV resistance. Not only MPO surpass PG in final coating performance, but also MPO has superior performance in manufacturing process control. The higher reactivity of MPO enables the polymerization reaction to finish faster and at a lower temperature, resulting in a shorter processing time and lower coloring in the final product. as the bar chart below illustrates.

Reduce Inventory Grades by Adopting MPO

There are many low molecular weight diols: EG, DEG, PG, DPG, BDO etc, are being used to make polyester polyol in formulation of coatings and foams. It is beneficial to consider MPO in such systems to reduce multiple grades in warehouse but offer multiple property improvements. Especially in foams, when water or aqueous solution is used as blowing agent, any residual moisture in foam cells can be detrimental to the life of foam structure. When MPO is used in foam base, its hydrolytic stability will alleviate the damage of moisture and elongate the work life of the foam.

Low Viscosity of MPO Polyester Polyol

In the MPO polyester polyol series, the viscosity increases with MW. The MW 1000 grade is a 3000 cps clear liquid at room temperature. Higher molecular weight grades have higher viscosities. These viscosities at room temperature and elevated temperatures are listed in this chart below:

MPO Improves Clarity of Parts

The water-clear physical appearance of the MPO polyester polyols is due to the random orientation that MPO molecules take in the ester chain and bring the amorphous structure into the polymer. For the same reason it offers the optic clarity to downstream products. This character gives MPO polyesters another unique position in clear product formulation.

MPO Application Overview:

While MPO properties offer a multitude of excellent properties, they are not good when used alone in high-hardness applications. When formulating this type of product, mixing MPO with raw materials that offer rigidity is the optimal strategy.

In summary, MPO polyester polyols are excellent raw material choices for flexible, outdoor applications like sporting grounds in warm or cold climate and also ideal for soft bedroom items. The intrinsic chemical structure drives long life cycles of MPO based products.

Besides what described above, there are many benefits MPO offers in many other applications, such as high abrasion resistance, can be used as a reactive plasticizer for PU, offer low Tg that avoids brittle in very cold applications, etc. For more information on MPO polyester polyols and our entire lineup of diols and polyols, contact Gantrade today here.

Gantrade technical team will work with you every step of the way.